Unpacking NFC Tag Heat Resistance: A Comprehensive Guide for Demanding Applications

Unpacking NFC Tag Heat Resistance: A Comprehensive Guide for Demanding Applications

1. Introduction: What are NFC Tags and Why is Heat Resistance Important?

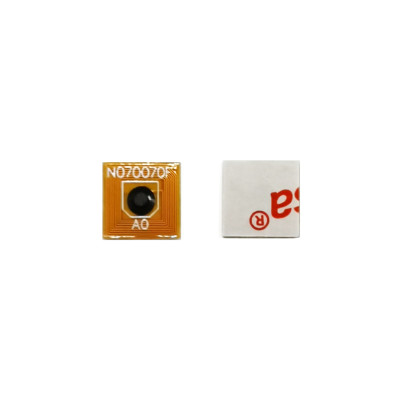

Near Field Communication (NFC) tags are small, passive devices that enable short-range wireless communication between two NFC-enabled devices, typically a smartphone and the tag itself. They operate at 13.56 MHz and are widely used for various applications, including contactless payments, access control, smart posters, and asset tracking. However, the operational environment often presents challenges, none more critical than temperature fluctuations. The question "Are NFC tags heat resistant?" is paramount for many industrial, medical, and manufacturing applications where tags must endure extreme thermal conditions without data loss or functional compromise.

2. The Core Question: Are Standard NFC Tags Heat Resistant?

Generally, standard NFC tags are not inherently highly heat resistant. Their design relies on components, such as a microchip, an antenna, a substrate, and an adhesive, which are all susceptible to damage or diminished performance when exposed to elevated temperatures . Most common NFC tags are designed to operate within a relatively narrow temperature range, often cited as -10°C to 50°C or -25°C to 75°C . Exceeding these limits can lead to signal degradation, data corruption, and even permanent physical damage to the tag.

3. Components of an NFC Tag: The Vulnerable Points

The heat resistance of an NFC tag is the sum of its parts. Each component has its own thermal tolerance, and the weakest link determines the overall heat resilience:

- The Chip (Integrated Circuit): The silicon chip is often the most sensitive component. Most standard silicon chips cannot operate reliably above 125°C (257°F). While they might survive higher temperatures, they won't function until they cool down.

- The Antenna: Typically made of etched aluminum or copper, the antenna can oxidize or deform under high heat, leading to signal loss and reduced read range.

- The Substrate/Substrate: This is the base material on which the chip and antenna are mounted. Common materials like PET (polyethylene terephthalate) or paper are not suitable for high temperatures and can melt, warp, or degrade.

- The Adhesive: The adhesive used to attach the tag to a surface is crucial. Standard adhesives can lose their bonding strength or chemically break down when exposed to significant heat, causing the tag to detach or its internal layers to delaminate.

4. Understanding Temperature Thresholds: Operating vs. Survival Temperatures

It's vital to distinguish between a tag's operating temperature and its survival temperature. Operating temperature refers to the range within which the tag can actively communicate and function as intended. Survival temperature, or storage temperature, indicates the range of temperatures the tag can endure without permanent damage, though it may not be operational during exposure. For example, some NXP NFC products have an operating temperature of -25°C to 75°C, but a storage temperature of -55°C to 125°C.

5. Materials for Heat Resistance: The Building Blocks of Durability

To overcome the limitations of standard tags, high-temperature NFC tags employ specialized materials for each component:

- Polyimide (PI): A common substrate for flexible high-temperature applications due to its excellent thermal stability.

- Polyphenylene Sulfide (PPS): Known for its high-temperature resistance, chemical stability, and mechanical strength, frequently used in laundry tags.

- Polyether Ether Ketone (PEEK): A high-performance engineering plastic offering exceptional heat, chemical, and wear resistance.

- Specialized Adhesives and Solders: Formulations designed to maintain integrity and bond strength at elevated temperatures.

6. The Role of Encapsulation: Protecting the Delicate Heart

Encapsulation is a critical factor in a high-temperature NFC tag's durability. It involves tightly wrapping the chip and antenna within heat-resistant materials, forming a sealed protective layer. This not only shields the internal electronics from direct heat but also from moisture, chemicals, and physical stress . Materials like reinforced PA6, durable PPS, or custom polymer compounds are used for the tag's housing, enhancing its overall resilience.

7. High-Temperature NFC Tags: Designed for Extremes

Specialized high-temperature NFC tags are engineered to perform in environments where standard tags would fail. These tags are not just resistant to heat; they are designed for specific high-stress applications. For instance, some industrial tags can withstand up to 230°C or 280°C, and even 300°C for shorter durations. They are often flexible, durable, waterproof, and designed for rugged use.

8. Key Applications Requiring Heat-Resistant NFC Tags

The demand for heat-resistant NFC tags comes from sectors where conventional labeling or tracking solutions are inadequate:

- Industrial Asset Tracking: Monitoring tools, equipment, and work-in-progress components in manufacturing lines, foundries, and heavy machinery, often exposed to high heat during production processes.

- Automotive and Aerospace: Tracking parts through painting, curing, and assembly processes that involve high temperatures. Tags help with traceability and anti-counterfeiting.

- Laundry and Textile Management: Washable high-temperature resistant NFC tags are used to track garments in commercial laundries, resisting hot water, detergents, and high-heat drying cycles (e.g., 100°C or higher).

- Medical Sterilization: Tracking medical instruments through autoclaves or other sterilization processes that involve high temperatures and steam.

- High-Temperature Equipment Monitoring: For specific components or machinery where temperature data or unique identification is needed in harsh thermal conditions.

9. Factors Influencing Performance in Heated Environments

Beyond the peak temperature, several other factors affect an NFC tag's performance in heated environments:

- Duration of Exposure: Prolonged exposure to high temperatures gradually degrades materials, even those designed for heat resistance.

- Repeated Thermal Cycles: Frequent heating and cooling can cause material fatigue and micro-cracks, leading to eventual failure.

- Thermal Shock: Rapid changes in temperature can induce stress, potentially causing delamination or cracking.

- Combined Stressors: Heat often comes with other environmental challenges like chemicals, pressure, moisture, or vibrations, which can collectively reduce a tag's lifespan.

10. Choosing the Right NFC Tag for Your High-Temperature Needs

Selecting the appropriate NFC tag requires careful consideration:

- Define Your Temperature Range: Determine the maximum operating temperature and any potential peak survival temperatures.

- Consider Other Environmental Factors: Account for exposure to chemicals, moisture, pressure, or vibrations.

- Application-Specific Design: Some tags are optimized for specific surfaces (e.g., metal, non-metal) or attachment methods (adhesive, embedded, sewn).

- Chip Type and Memory: While most NFC chips can withstand temperatures up to their limits, ensure the specific chip (e.g., NTAG series) meets your functional requirements.

- Testing and Certification: Look for tags that have undergone rigorous testing for their stated temperature limits and relevant industrial standards.

11. Future Trends in NFC Heat Resistance

The evolution of materials science and micro-manufacturing continues to push the boundaries of NFC tag capabilities. We can expect:

- Wider Temperature Ranges: Development of new polymers, ceramics, and chip technologies that can sustain even higher temperatures for longer durations.

- Integrated Sensing: More NFC tags with integrated temperature sensors, allowing for passive monitoring of environmental conditions by simply scanning the tag.

- Miniaturization: Smaller, more robust tags that can be embedded into an even wider array of products and components without compromising thermal performance.

- Enhanced Data Retention: Improvements in memory technology to ensure data integrity even under extreme thermal stress.

12. Conclusion: Navigating the Heat Challenge with NFC Technology

While the answer to "Are NFC tags heat resistant?" is nuanced – generally no for standard tags, but a definitive yes for specialized ones – the capabilities of NFC technology in high-temperature environments are continuously expanding. By understanding the critical role of advanced materials, robust encapsulation, and specific design considerations, industries can leverage these durable NFC solutions to ensure reliable tracking, identification, and data management even in the most thermally challenging conditions. The ongoing innovations in this field promise even greater resilience and broader applications for NFC tags in the future.